HANDLING AND PACKING

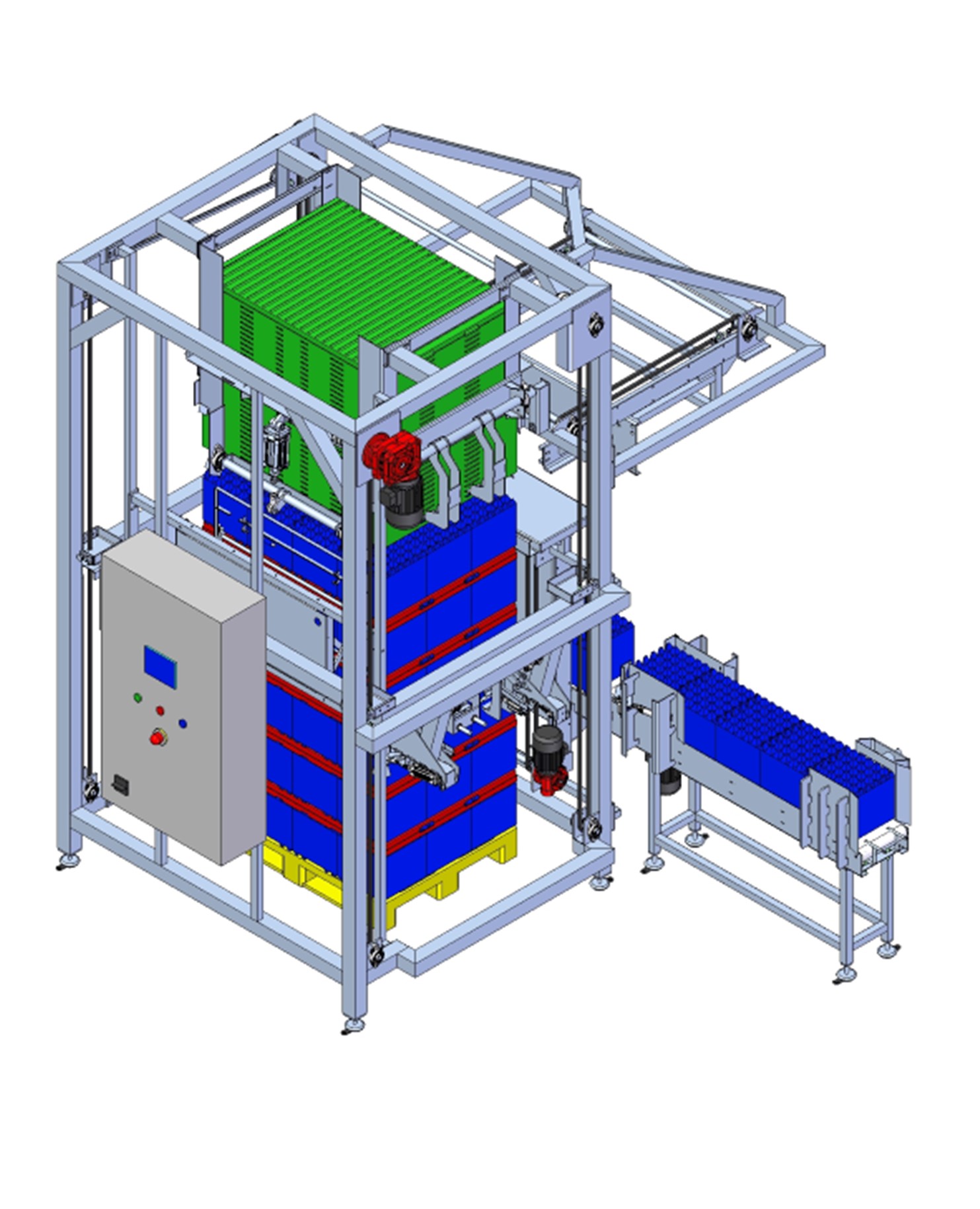

Can be used to handle anything that needs to be stacked or de-stacked

The gripping tool can be designed to fit your requirements

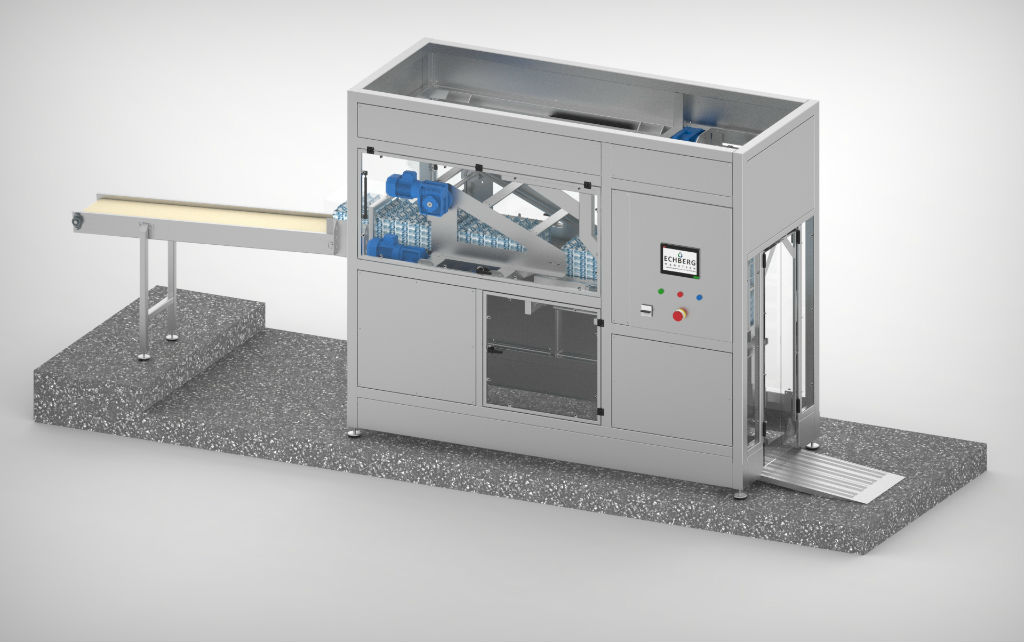

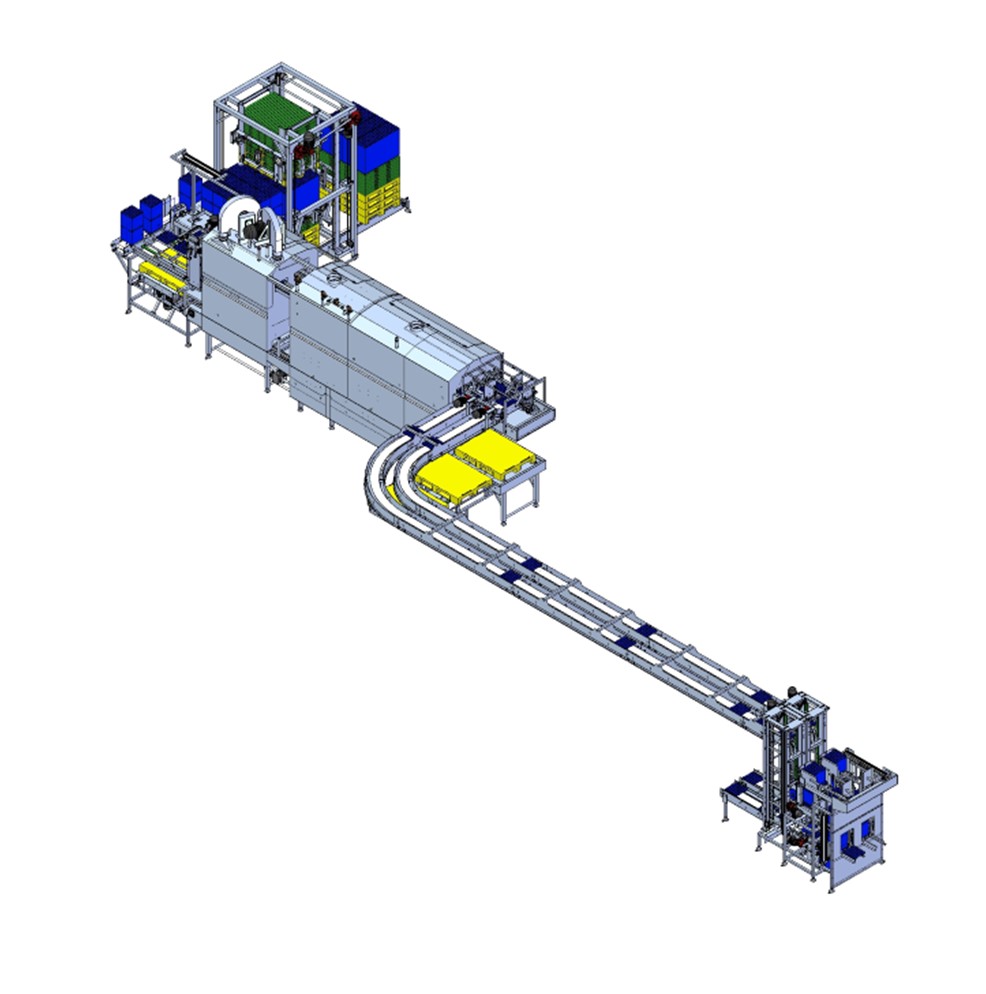

A washing machine can be combined with a robot for handling of washing items

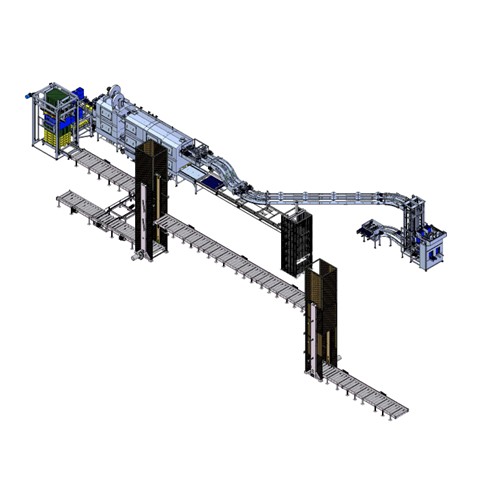

Automatic line for cleaning and sorting of pallets, designed for your needs

Is built up in modules, and can therefore easily fit any costumer requirement

We cooperate directly with your service organization to ensure fast service

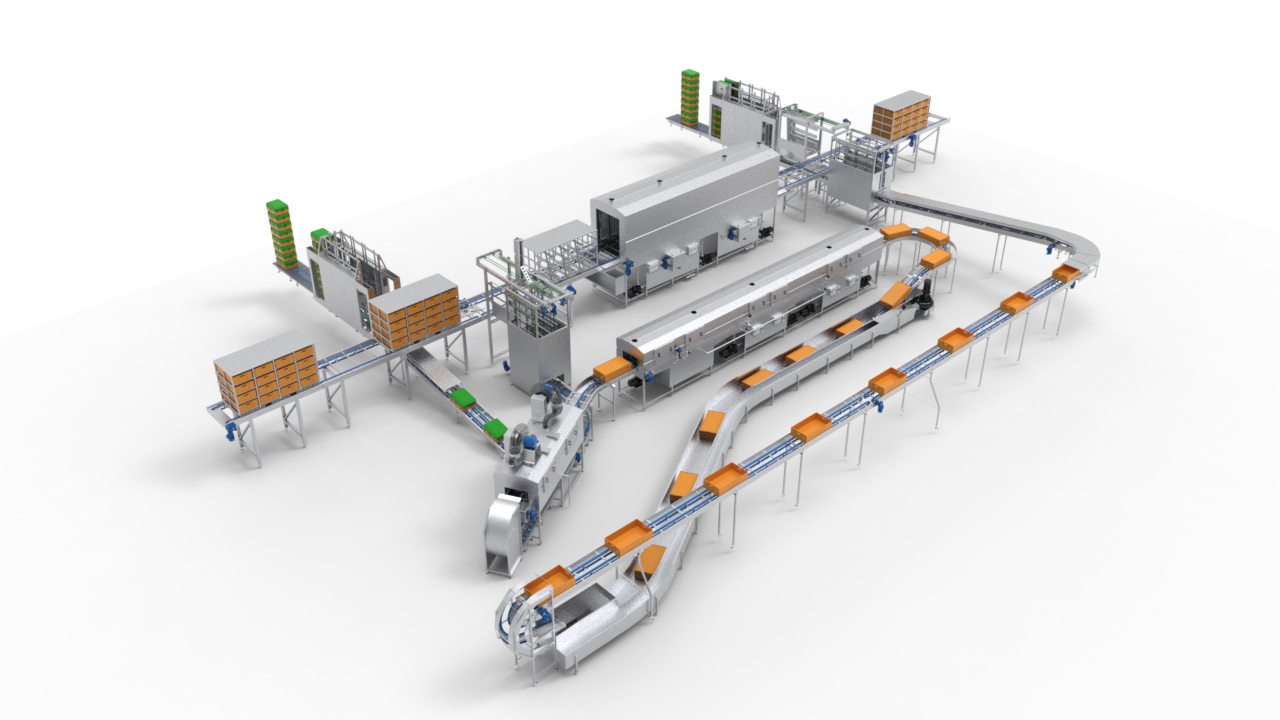

Inline automation before and after washing, designed for your needs and applications

Stainless steel design for high level of hygiene and easy to clean and maintain

Good flexibility in production design due to customer designed washing solution

For use in the dairy industry for packing milk cartons, poly bottles etc.

Can pack onto standard three or four high trolleys with or without shelves

We cooperate directly with your service organization to ensure fast service

For use in cheese dairies where Horden frames needs to be stacked or destacked

Easy access to all parts for cleaning and service

Stainless steel design for high level of hygiene and easy to clean and maintain

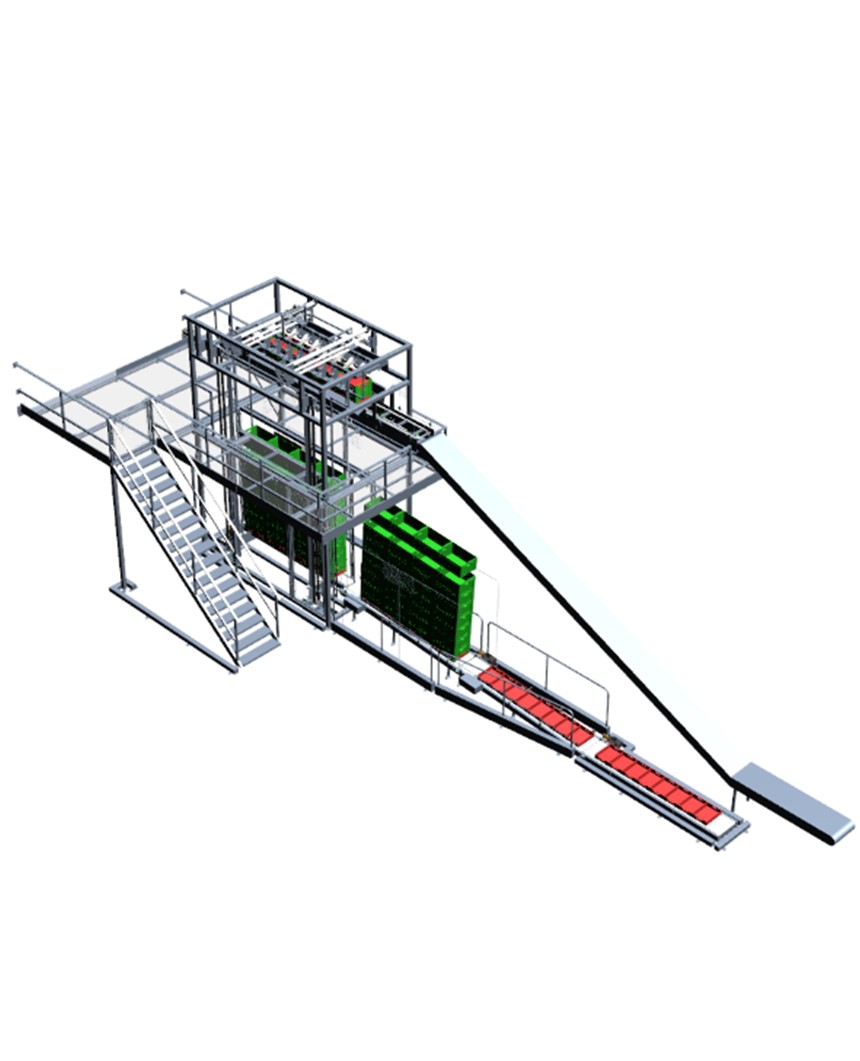

Inline palletizing results in better internal logistic

Automatic buffer system increases production

Stainless steel design for high level of hygiene and easy to clean and maintain

Inline automation after farm packer machine, designed your needs

Stainless steel for high level of hygiene and easy to clean design

Good flexibility in production design due to customer design of handling solution

Can be used to handle anything that needs to be stacked or de-stacked

The gripping tool can handle different box dimensions simultaneously

A washing machine can be combined in an inline system

Direct connection to loader, reducing manpower and increasing productivity

Automatic buffer system increases production time

Inline washing result in better cleaning

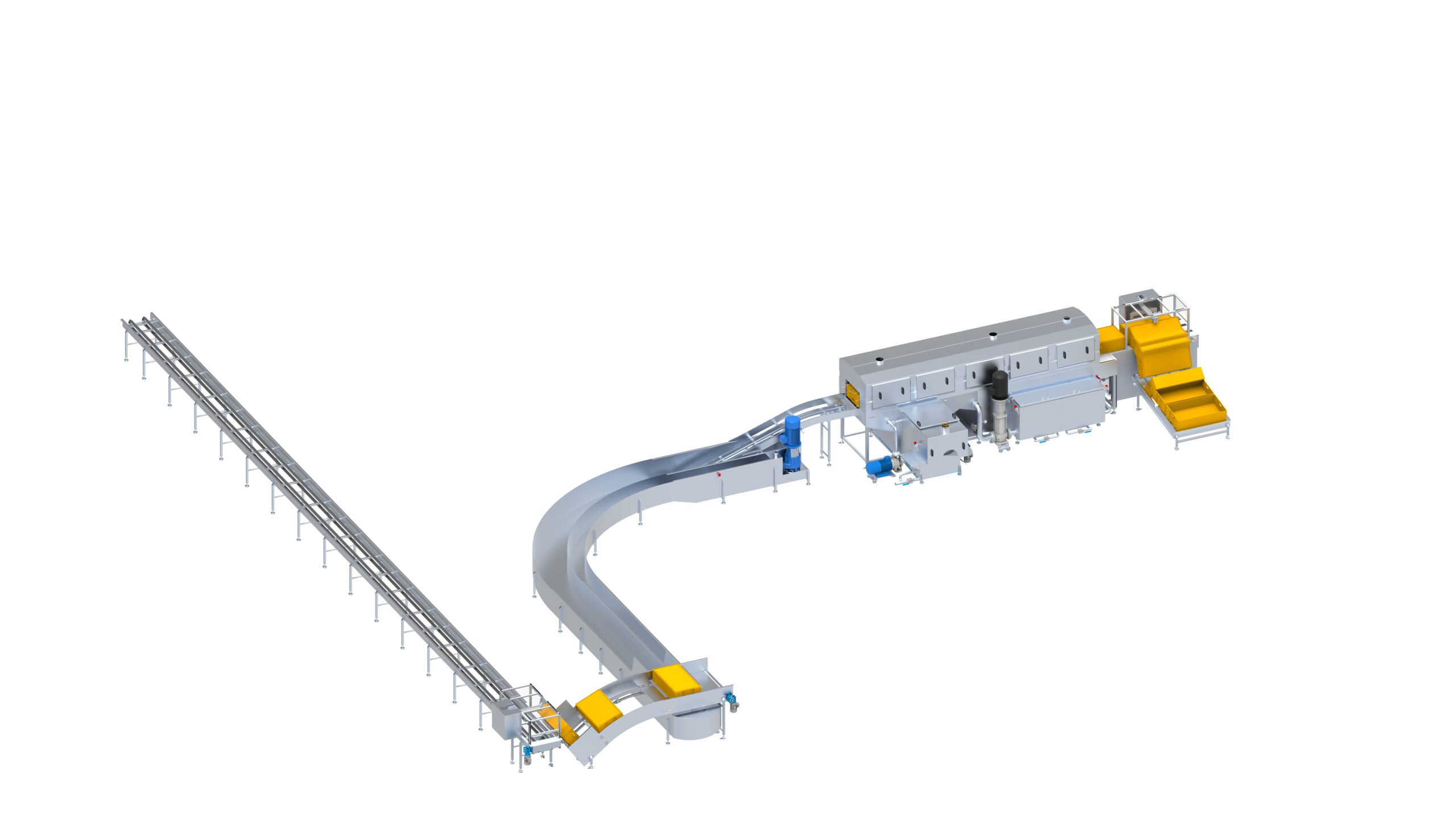

High velocity air is led from the fans through the special designed air knives

Can easily fit onto existing production lines

Can be used in any industry, which washes trays, crates, containers etc.

Washing capacity is 750-1200 crates for live bird per hour

Combi washing designed for local and modular crates in same machine

Good flexibility in production design due to small footprint and high capacity

Washing capacity is 300-500 crates for live bird per hour

Combi washing designed for local and modular crates in same machine

Good flexibility in production design due to small footprint and high capacity